Abstract

This project focuses on the design and development of a next-generation Remotely Operated Vehicle (ROV) at Potential Robotics, blending mechanical design, electronics, and advanced autonomy. From building a proprietary controller using PixHawk and MavROS to implementing multimodal sensor fusion for underwater localization, this ROV project was an end-to-end challenge in harsh aquatic environments. The work spanned hardware prototyping, custom ROS-based architectures, thruster testing, and a web-based digital twin UI — all aimed at pushing underwater robotics closer to reliable real-world deployment.

Introduction

Underwater environments present some of the toughest challenges in robotics: low visibility, unreliable GPS, unpredictable currents, and high hardware stress. At Potential Robotics, I worked on developing a robust ROV platform that could not only handle these challenges but also provide accurate localization, reliable control, and intuitive operator interfaces.

Motivation

Unlock underwater environments for research, inspection, and exploration.

Provide robust autonomy where humans can’t easily go (deep water, murky visibility, dangerous areas).

Build a modular platform for testing thrusters, sensors, and control systems in real-world aquatic conditions.

System Overview

ROV Control

Built a proprietary controller leveraging PixHawk PX4 and MavROS.

Integrated ROS-based communication for sensors, thrusters, and power systems.

Added CAN (J1939) protocol support for power monitoring and comms.

Localization & State Estimation

Implemented DVL-based dead reckoning.

Expanded to multimodal sensor fusion:

Doppler Velocity Log (DVL)

Cerulean Sonar

Depth Camera

On-board IMU

Built fusion pipelines for robust state estimation and localization.

Designed an IMU-based stabilization system:

Used real-time orientation data (roll, pitch, yaw) for closed-loop control.

Stabilized the ROV against external disturbances and thruster noise.

Improved hover and station-keeping performance in turbulent water.

Hardware Contributions

Assisted with electronics design, wiring, assembly, and machining.

Built and tested a thruster benchmarking rig to compare market thrusters with in-house designs.

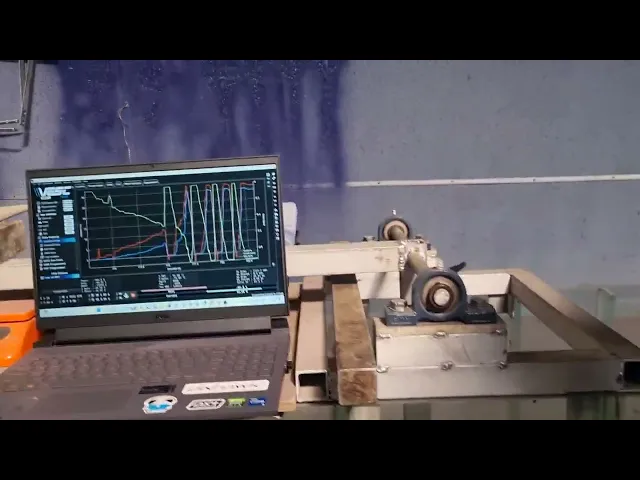

Thruster Test Bench

One of the key pieces of hardware I developed was a thruster benchmarking test bench:

Designed and built a modular rig to mount and test different thruster models under controlled conditions.

Instrumented the bench with sensors to measure thrust, torque, and power draw.

Compared commercial thrusters with in-house designs to evaluate efficiency, responsiveness, and durability.

This allowed the team to select the most effective thrusters for the ROV while reducing wasted costs on underperforming units.

Software Architecture

Single-handedly designed and implemented a ROS-based communication architecture handling:

Sensor integration

Thruster feedback loops

Power pack monitoring

Control systems

Developed proprietary web-based UI for real-time monitoring:

Built with React, Flask, ThreeJS, and ROS

Visualized ROV 3D model synced with real robot motions

Showed live battery, depth, speed, sensor streams, and camera feeds

Real-time side-scan sonar visualization

Mapping & Perception

Integrated SideScan Sonar and Ping360 sonar.

Attempted underwater mapping using sonar and visual sensors.

Connected low-light HD cameras and Raspberry Pi-based compute modules.

Pipeline Diagram (Conceptual)

Controller (Pixhawk PX4 + MavROS) → Thruster & power pack control

Sensor Suite (DVL, Sonar, IMU, Depth Camera) → State estimation & mapping

ROS Comms Layer → Synchronizes data across systems

Digital Twin UI (React + Flask + ThreeJS) → Operator visualization and monitoring

ROV Hardware → Real-time actuation + feedback loop

Results

Achieved robust state estimation using DVL + sonar fusion.

Built and validated a thruster test bench to compare performance.

Created a live digital twin interface, enabling intuitive remote operation and monitoring.

Successfully integrated multi-sensor architecture under ROS, including CAN-based power systems.

Progress toward underwater mapping using sonar was initiated.

Conclusion

Working on the Potential Robotics ROV taught me how messy, unpredictable, and exciting underwater robotics can be. From wrestling with sensor fusion to wiring up thrusters, every piece of the system required creativity and persistence. The end result was more than just a robot — it was a full-stack platform that blended mechanical engineering, electronics, autonomy, and software design into a single underwater machine.